On my recent trip to China, I had the privilege of visiting the EP factory—a hub of innovation and sustainability. Here, I witnessed their groundbreaking work in remanufacturing forklift trucks. This remarkable initiative showcases EP’s dedication to reducing industrial waste while delivering high- quality, eco-friendly machinery

Why Remanufacturing Matters

In a world increasingly focused on sustainability, remanufacturing offers a vital solution to extend product lifecycles and minimize waste. EP has redefined this concept by transforming used forklifts into high-performance machines that meet the demands of modern industries.

But remanufacturing is not just refurbishing. It’s about restoring equipment to like-new condition with meticulous precision. This process saves raw materials, reduces carbon emissions, and offers cost- effective, eco-conscious solutions for businesses worldwide.

A Walk Through the Remanufacturing Process

EP’s remanufacturing facility is a marvel of engineering and environmental ingenuity. Here’s an insider’s look at the four key stages:

1. Disassembly and Inspection

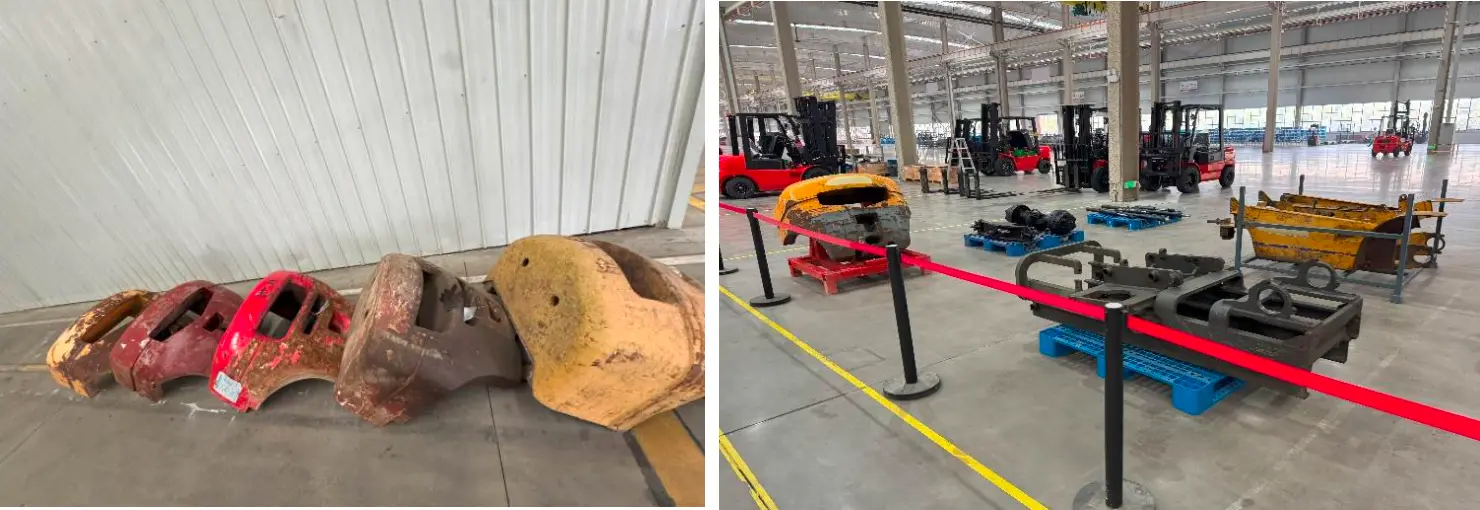

The process begins with a detailed inspection in the intake area. Each forklift is evaluated for its remanufacturing potential before being disassembled into core components. From engines to hydraulic systems, every part is inspected for wear and tear.

Disassembly and Inspection

2. Component Restoration

Restoration is where precision meets sustainability. Salvageable parts are meticulously cleaned, repaired, or machined to meet stringent specifications. Components that don’t make the cut are responsibly recycled, reinforcing EP’s commitment to eco-friendly practices.

Component Restoration

Bringing vital components back to life - restored to perform as good as new.

3. Reassembly and Upgrades

During reassembly, each forklift is rebuilt using a blend of restored and brand-new components. Modern upgrades, such as advanced control systems and energy-efficient features, are seamlessly integrated, ensuring these forklifts meet today’s market demands.

Reassembly and Upgrades

4. Quality Testing

Every remanufactured forklift undergoes rigorous quality testing, including load handling, braking efficiency, and durability trials. Only after passing these exhaustive tests are the forklifts deemed ready for shipment.

Quality Testing

Sustainability at the Forefront

EP’s remanufacturing initiative exemplifies their broader commitment to sustainability. By extending the life cycle of forklifts, the company significantly reduces industrial waste and conserves raw materials. The facility itself is designed to minimize its carbon footprint, incorporating energy-efficient technologies and renewable energy sources.

Sustainability at the Forefront

The Final Product: Innovation Meets Sustainability

Seeing the finished forklifts lined up for shipping was inspiring. With their fresh paint, updated features, and like-new performance, it’s hard to believe they were once used equipment. This transformation highlights the ingenuity behind remanufacturing and its potential to revolutionize industries.

The Final Product: Innovation Meets Sustainability

Reflections and Takeaways

My visit to EP’s factory left me optimistic about the future of sustainable manufacturing. EP’s remanufactured forklifts prove that businesses can embrace circular economy principles without compromising quality or performance.

For companies seeking cost-effective, reliable, and eco-conscious solutions, these forklifts are a perfect fit. If more industries adopt this forward-thinking approach, we could see a significant shift toward resource-efficient practices across the globe.

Ready to Learn More?

Explore the benefits of remanufactured forklifts and how they can drive sustainability in your operations. Visit our website or Contact us today to discover eco-friendly industrial solutions tailored to your needs.